Marketplace Pulse: Injection Molding RFQs

Injection Molding Manufacturers on the Marketplace are closing business each day. Get in on the action now! Create Your AccountLooking to find new customers and submit quotes on custom jobs in your special capabilities? Create your profile and grow your manufacturing business today!

If you have questions or need support, please contact us directly at support@mfg.com.

What is Injection Molding?

Injection Molding is the process of injecting plastic into an aluminum or steel mold to form the part. Injection molding is a great process for low and high volume manufacturing. It is widely used in the medical, automotive, industrial, construction and consumer product industries. Some advantages of injection molding are high production rates, repeatable high tolerances, the ability to use a wide range of materials, low labor cost, minimal scrap losses, and little need to finish parts after molding. Some disadvantages of this process are expensive equipment investment, potentially high running costs, and the need to design moldable parts.

Bookmark and refresh this page often to see the newest RFQs.

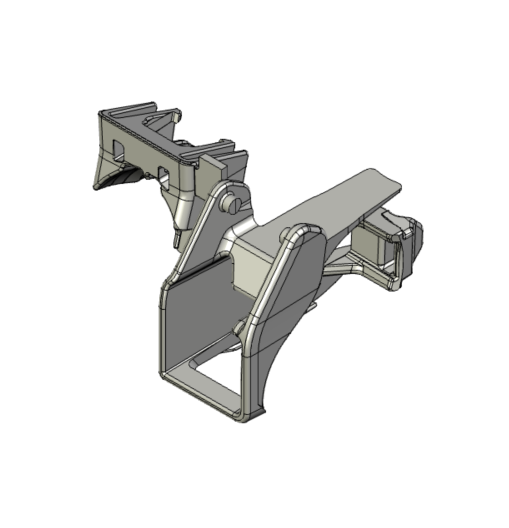

Injection Molded Duct Parts

RFQ ID: 1211422Injection Molding

Injection Molding

MATERIAL_PLASTICS_&_RUBBER_THERMOPLASTIC

Yes

2,000

Stackable Food Storage Containers

RFQ ID: 1211577Injection Molding

Injection Molding

MATERIAL_PLASTICS_&_RUBBER_THERMOPLASTIC

No

1,000

FH-10008

RFQ ID: 1211732PDC BODY AND LID

RFQ ID: 1211730Injection Molding

Injection Molding

MATERIAL_PLASTICS_&_RUBBER_ELASTOMER

Yes

750

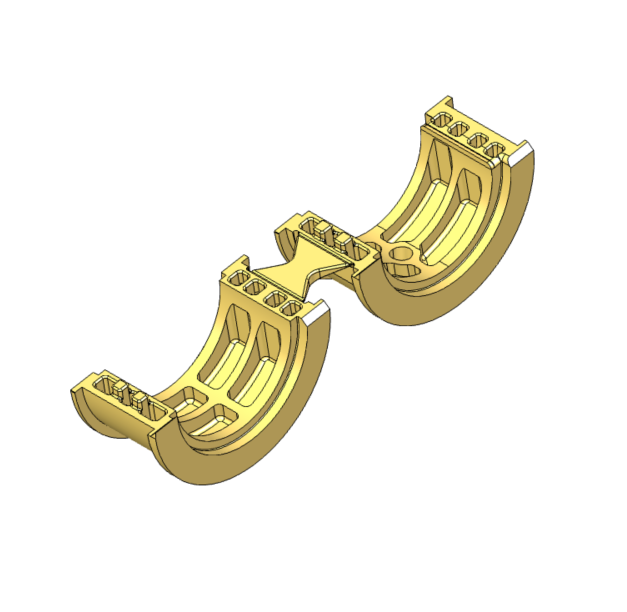

H-Saddle

RFQ ID: 1211760Injection Molding

Injection Molding

MATERIAL_PLASTICS_&_RUBBER_THERMOPLASTIC

No

1,000

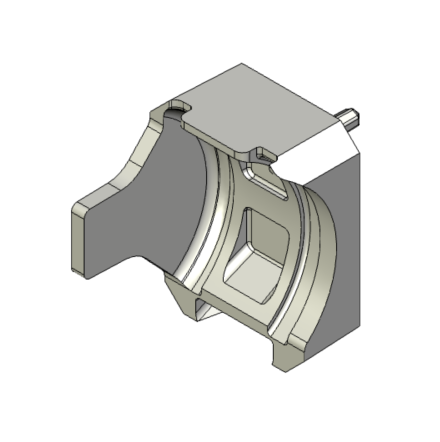

BHS-Barrel Spacer LD

RFQ ID: 1211762Injection Molding

Injection Molding

MATERIAL_PLASTICS_&_RUBBER_THERMOPLASTIC

No

1,000

LD Saddle

RFQ ID: 1211761Injection Molding

Injection Molding

MATERIAL_PLASTICS_&_RUBBER_THERMOPLASTIC

No

1,000