Marketplace Pulse: Thermoforming RFQs

Thermoforming Manufacturers on the Marketplace are closing business each day. Get in on the action now! Create Your AccountLooking to find new customers and submit quotes on custom jobs in your special capabilities? Create your profile and grow your manufacturing business today!

If you have questions or need support, please contact us directly at support@mfg.com.

What is Thermoforming?

Thermoforming is a process of heating a thermoplastic sheet to its softening point and using a vacuum, pressure, or mechanical force to form the material onto a mold surface. The forming force is maintained on the part until the material cools and solidifies. The excess material is then trimmed away and the formed part is released from the mold.

In vacuum forming, a vacuum is formed between the mold cavity and the thermoplastic sheet. The vacuum pressure forces the sheet to conform to the mold and form the part shape.

In pressure forming, in addition to utilizing a vacuum underneath the sheet, air pressure is applied on the back of the sheet to help force it onto the mold. The additional force allows the forming of thicker sheets and creating finer details, textures, sharp corners, and undercuts.

In mechanical forming, the thermoplastic sheet is mechanically forced into or around the mold by direct contact from a core “plug”. The core plug is a supplemental mold component which pushes the sheet onto the mold cavity and forms it into the desired shape.

Bookmark and refresh this page often to see the newest RFQs.

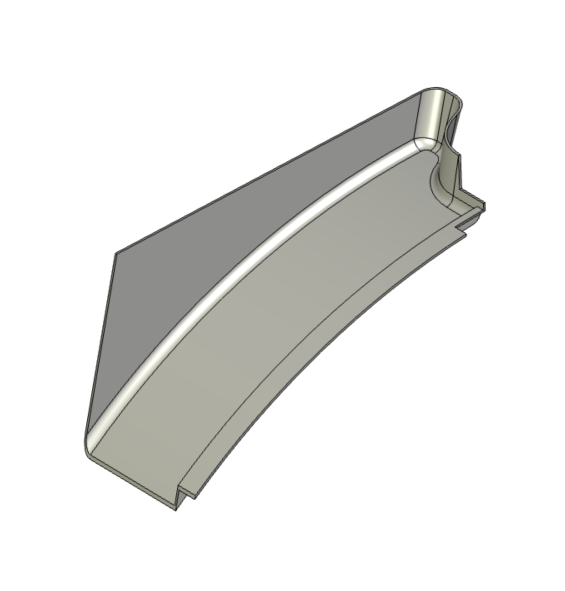

Sprinter Corner Blocks

RFQ ID: 1211753Thermoforming

Thermoforming

MATERIAL_PLASTICS_&_RUBBER_THERMOPLASTIC

Yes

12